Slurry Wall Concrete Mix Design

Cement bentonite slurry wall mix design christopher r.

Slurry wall concrete mix design. Because of the relative simplicity. To prevent the concrete wall from collapsing into the newly open area temporary supports such as tiebacks or internal crossbeams are installed. Concrete mix design and workability shall be consistent for tremie or pump placement. Vertical concrete mix for resurfacing walls discover the best vertical mixes for skim coating a concrete wall updated august 11 2020.

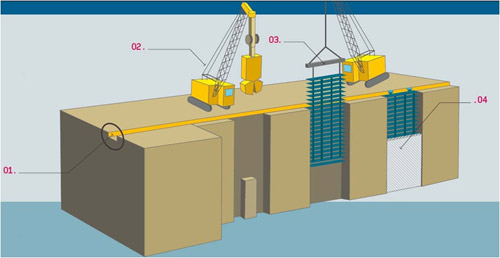

Conventional reinforced concrete diaphragm crc walls. In this type of wall the reinforcing cage is designed to span vertically with no structural continuity between adjacent panels. Glenn 164 172 181 194 207 225 235 251 seepage cutoffs design and construction of a plastic concrete cutoff wall for the island copper mine r. This mixture is capable of filling all voids in irregular excavations and hard to reach places such as under undercuts of existing slabs is self leveling and hardens in a matter of a few hours without the need for compaction in layers.

But a number of companies now sell convenient. Advantages of soil bentonite slurry walls. Some contractors who specialize in vertical work have developed their own wall mixes based on tried and true formulas. Start with equal parts cement and water and then add more cement until you have the desired consistency.

Bag of vertical concrete mix from flex c ment. Plastic concrete slurry wall for wister dam e. In the us the sb slurry wall technique is used far more frequently than any of the other slurry trench construction methods cement bentonite or soil cement bentonite. Circumferential walls with a cap.

Concrete consolidation during placement. Flowable fill concrete is a self compacting cementitious slurry consisting of a mixture of fine aggregate or filler water and cementitious material which is used as a fill or backfill in lieu of compacted soil backfill. Compared to other barrier wall types soil bentonite slurry walls offer the following advantages. Once the concrete has hardened excavation within the now concrete wall enclosed area can proceed.

To choose a slurry wall as a remedial measure should consider the continuing obligation to replace or propose a new remedy at the end of the slurry wall design life. The most common type of slurry wall is the conventional reinforced concrete diaphragm wall. In particular the concrete slump should be 8 inches 1 inch for tremie or slurry construction and 7 inches 1 inch for all other conditions. A low permeability slurry barrier may be upgradient of downgradient of or completely encircle circumferential slurry wall contamination.

When completed the structure built within the walled off area supports the wall so that tiebacks or other temporary bracing may be removed. Fortified concrete slurry varies slightly because it replaces some of the water with a polymer admixture for strength and flexibility. The ratio for a basic concrete slurry mix is 1 or 2 parts portland cement to 1 part water.